An impeller-powered flocculation basin is to be designed for a tertiary treatment plant for a flow of 94600 m 3 d. Design a horizontal flow baffled channel flocculatorfor a treatment plant of 10000m 3day capacity.

Flocculation Basin Water Treatment Waste Water Treatment Water Treatment Process Plant Design

Using a diameter-to-width ratio of 03 the impeller diameter would be.

. Volume ft 3 50 ft x 19 ft x 8 ft. The GT value should be from 50000 to 100000. The plant is to employ alum coagulation and pertinent data for the flocculation basin are as follows.

A pneumatic flocculation basin is to be designed for a tertiary treatment plant having a flow of 19000 m 3 d. The following conditions apply to the design. This preview shows page 1 - 2 out of 3 pages.

Top volume 267 m 6675m area depth 4m and Sides 6675m 817m. Impeller 817 m 03 245m diameter. The total flocculation time is to be 21 min and the water temperature is 15 C.

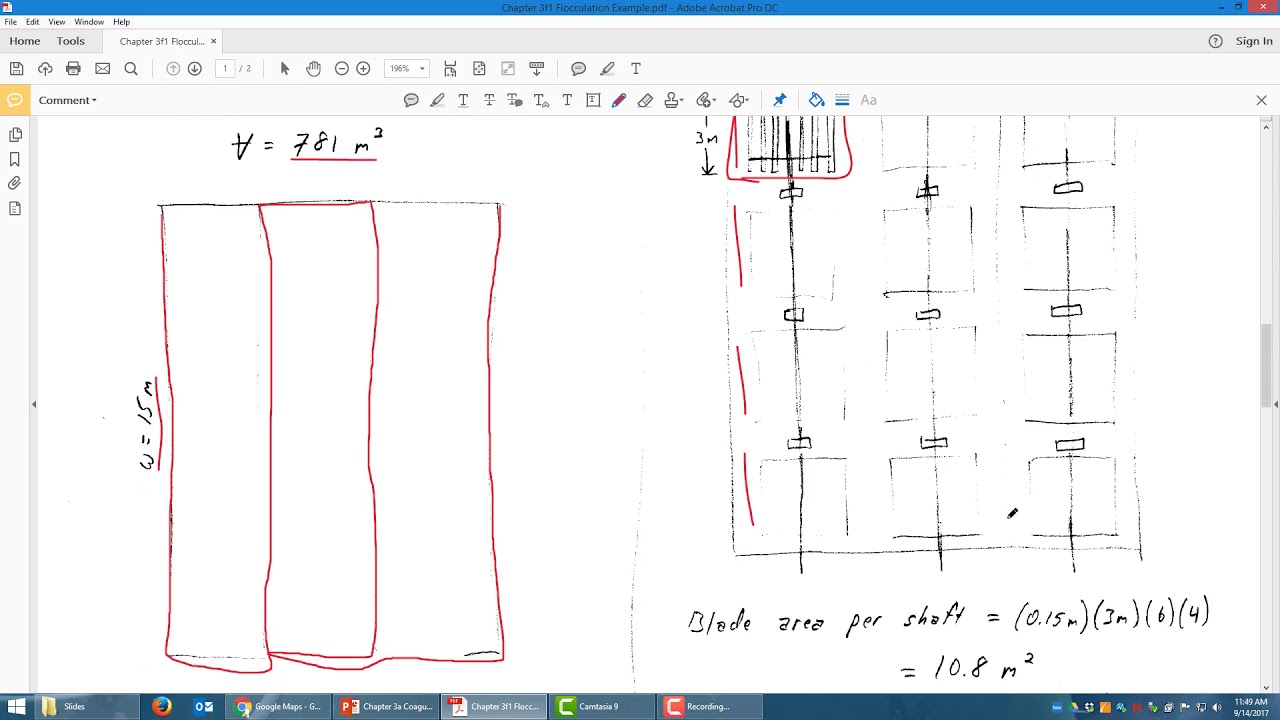

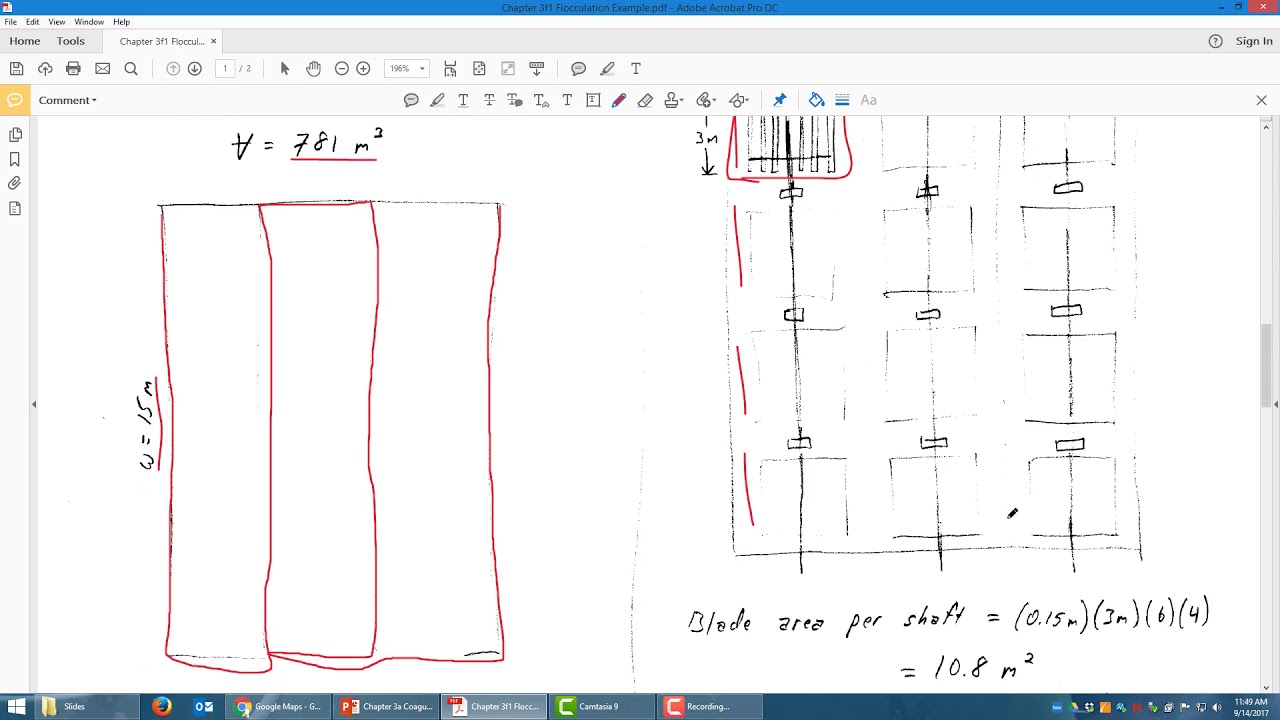

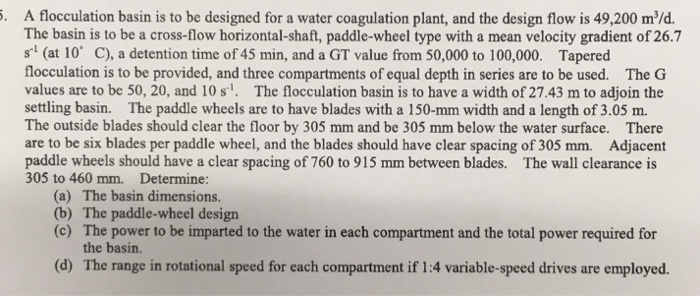

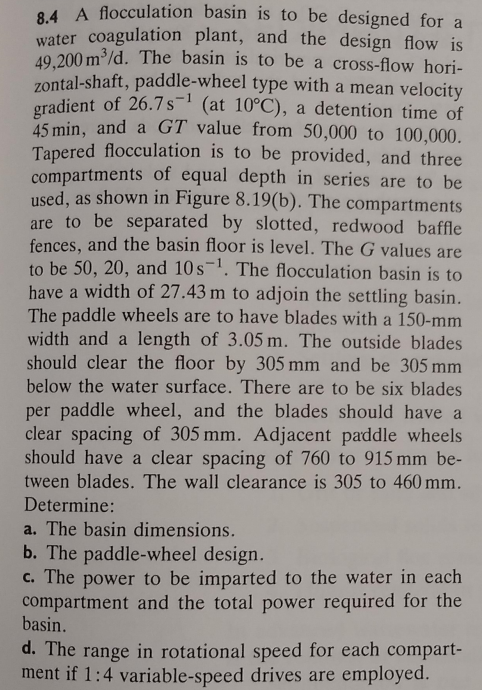

A flocculation basin is to be designed for a water coagulation plant and the design flow for the basin is 49200 m3day. A flocculation basin is to be designed for a water coagulation plant and the design flow for the basin is 130 MGD. The basin is to be a cross-flow tapered agitation system with a total detention time of 45 min.

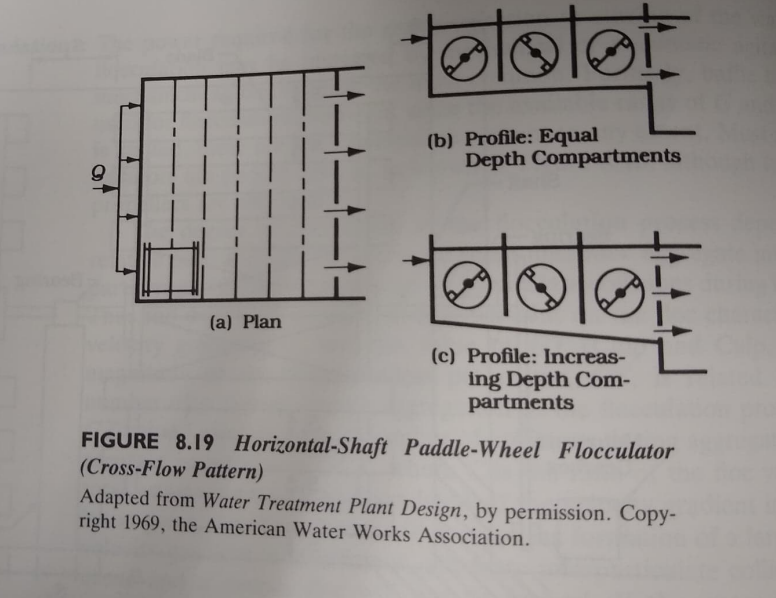

Detention time 20 min G 35 s 1 at 10C GT 10000 to 100000 width 125 times depth length twice width no baffling number of impellers 2 number of blades. 3 2 2 12. Example Problem A cross-flow horizontal-shaft paddle-wheel flocculation basin is to be design for a flow of 65 MGD a mean velocity gradient of 30 s -1 at 50F and a detention time of 50 min.

Detention time 5 min G 150s 1 at 10C length 2 times width depth 30m diffuser depth 275m. The basin is to be squared with a depth equal to 125 times the width. A single rectangular sedimentation basin is to be designed to treat a water flow of 15 MGD at the design overflow rate of 900 gpdft2.

10 Pts Determine the basin dimensions width length depth for a detention time. And air flow 680 m 3 h per diffuser. A cross-flow horizontal shaft paddle wheel flocculation basin is to be designed for a flow of 25000m3d a mean velocity gradient of 267sec at 10C and a detention time of 45 minutes.

The flocculation basin has a width of 2743 m to connect with the adjacent sedimentation system. A flocculation basin is to be designed for a water coagulation plant and the design flow for the basin is 49200 m 3 day. The Gt value should be from 50000 to 100000.

A cross-flow horizontal shaft paddle wheel flocculation basin is to be designed for a flow of 25000m3d a mean velocity gradient of 267sec at 10C and a detention time of 45 minutes. A flocculation basin is to be designed for a water coagulation plant and the design flow for the basin is 49200 m 3 day. The flocculation basin has a width of 2743 m to connect with the adjacent sedimentation.

The flocculation basin has a width of 2743 m to connect with the adjacent sedimentation. Water temperature of 10 oC total mean detention time of 45 min basin depth of 35 m 3 parallel trains of flocculators each train receives one third of the. Sustainable Municipal Drinking Water Treatment Monroe Weber-Shirk 4 The design inputs for flocculation We need collisions and thus G is a logical design specification.

Assuming a typical water depth of a flocculator of 4 m and a square tank arrangement the dimensions of the tank compartment would be. Assume a water temperature of 10 C a detention time of. Coagulation A rapid mixing basin is to be designed for a water coagulation plant and the design flow for the basin is 4MGD.

A hydraulically mixed flocculation basin is to be designed for a water treatment plant that has a capacity of 100000 m3day. First determine the volume of the flocculation basin in feet. The velocity gradient is to be 900 S-1 at 500F and the detention time is 30 sec.

The flocculation basin is 8 feet deep 19 feet wide adn 50 feet long. It seems prudent therefore to design flocculat-ing and mixing equipment with over-sized variable-speed drives so that the mixing intensity can be adjusted to suit changing conditions. They enable floe to toler-ate higher mixing intensities.

Volume ft 3 Length ft x Width ft x Depth ft. Flocculation tanks are to be designed for a total flow rate of 49200 m3d. To prevent floc from tearing apart or shearing the mixing velocity and energy are usually tapered off as the size of floc increases.

The flocculator is to be of an around-the-bend baffled basin. Volume ft 3 7600 ft 3. The basin is to be a cross-flow tapered agitation system with a total detention time of 45 min.

Flocculation Design 6 points. The GT value should be from 50000 to 100000. Flocculation aids are being used in-creasingly.

The flocculation basin is to be divided into 3 sections of equal volume each section having constant velocity gradients of 50 35 25 s-1 respectively. Calculate the detention time in minutes. The velocity gradient varies as the three-halves.

Tapered flocculation is to be provided and the three compartments of equal depth in series are to be used. The basin is to be a cross-flow tapered agitation system with a total detention time of 45 min. The plant is to employ high-pH lime coagulation and pertinent data for the flocculation basin are as follows.

A The basin dimensions if increments of 1in. A plant treats a flow of 24 MGD. The basin is to be a cross-flow horizontal-shaft paddle-wheel type with a mean velocity gradient of 267sec 1 at 50F a detention time of 45 min and a GT value from 50000 to 100000.

Design contact times for flocculation range from 15 or 20 minutes to an hour or more and flocculation requires careful attention to the mixing velocity and amount of mix energy.

Flocculation Basin Design Example Youtube

Solved A Flocculation Basin Is To Be Designed For A Water Chegg Com

8 4 A Flocculation Basin Is To Be Designed For A Chegg Com

8 4 A Flocculation Basin Is To Be Designed For A Chegg Com

Flocculation Basin Water Treatment Waste Water Treatment Water Treatment Process Plant Design

1 4 Coagulation And Flocculation Workforce Libretexts

Solved 6 A Flocculation Basin Is To Be Designed For A Water Chegg Com

0 comments

Post a Comment